2014

Hydraulic Laboratory of the School of Civil Engineering in Vysoké Mýto

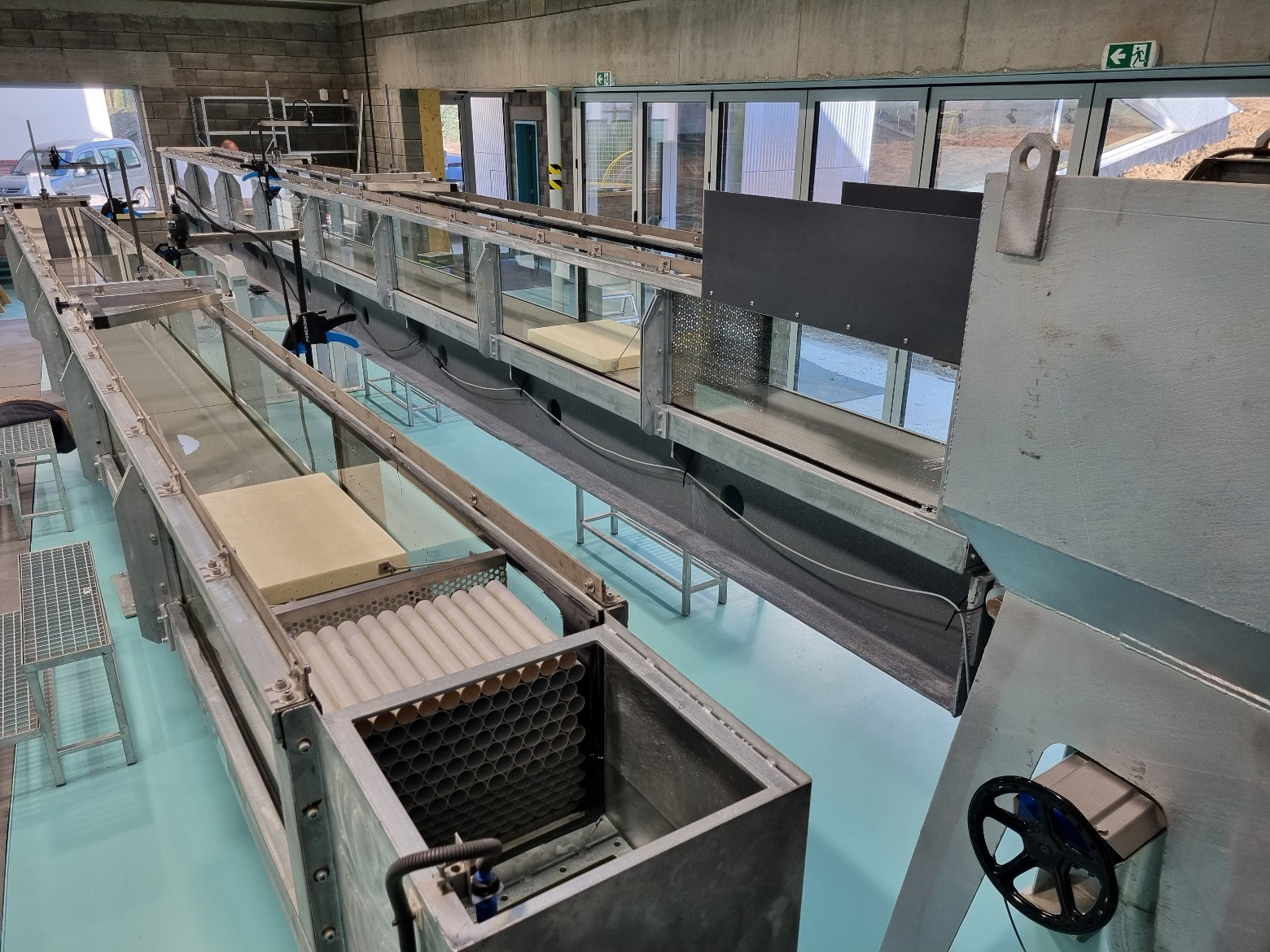

The hydraulic circuit of the laboratory consists of three basic elements – s storage tank, distribution pipes and connected measuring tracks.

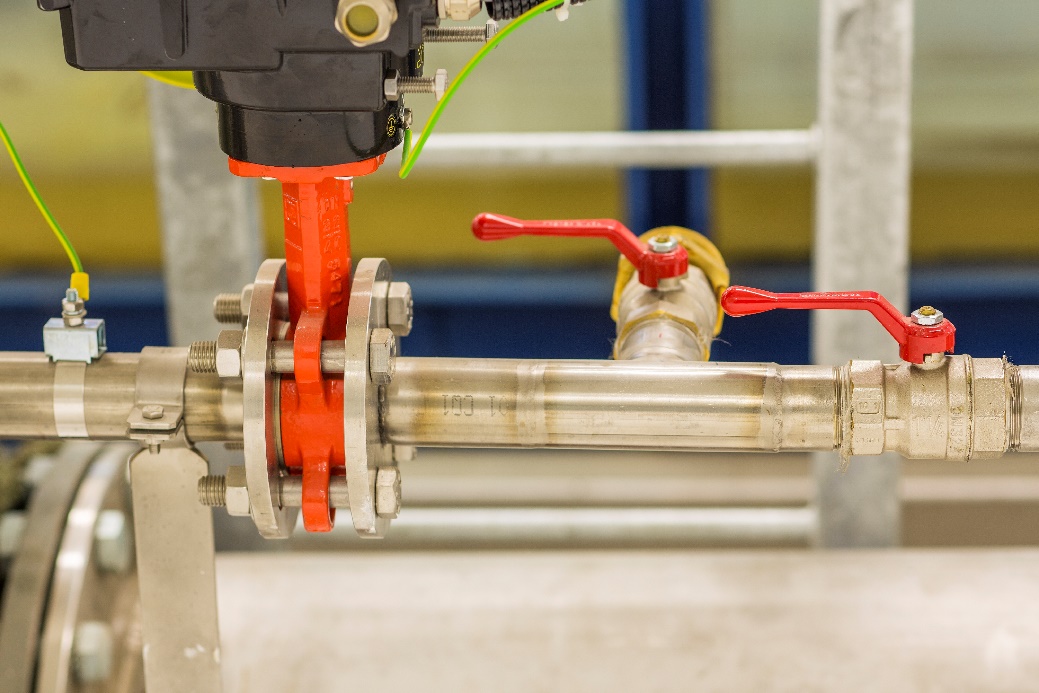

The underground storage tank, which also makes up a pumping and storage reservoir, is of rectangular ground plan with a total capacity of 6.5 m3. In the tank, there are two submersible centrifugal pumps with a total

power input of 4 kW and a maximum capacity of 36 l/s. The water is transported from the pumps by a stainless steel pipeline to two pressure branches of the hydraulic circuit in dimensions DN 100 and DN 50.

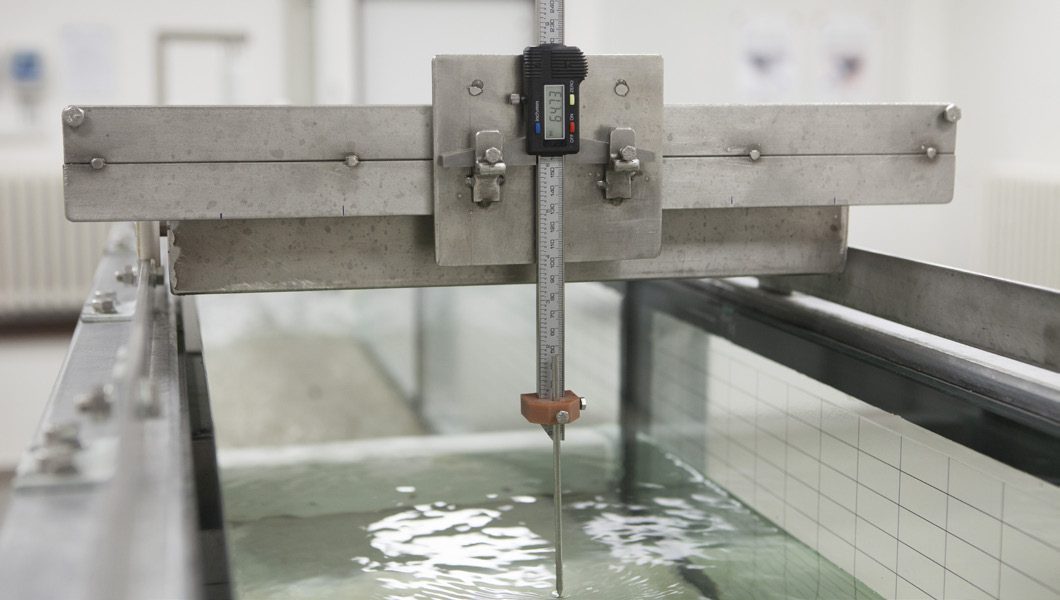

As part of the hydraulic circuit, a total of three measuring tracks were designed, of which the most important is a hydraulic measuring flume with a total length of 6.50 m. It is designed as a fixed flume, non-folding

with glazed side walls, a stainless steel bottom and a width of 0.36 m. The whole structure of the measuring flume is galvanized.

The second of the three tracks is a pressure operated measuring track which serves for simulation of the mechanical losses of energy by friction along the pipeline length and the local losses. The last of the three

tracks is a spare track which will be later used for supplying standalone models.

The hydraulic circuit delivery includes hydraulic models of structures. For the presentation of flow in the hydraulic measuring flume, 5 sharp-crested spillways, a streamline spillway and a dismountable culvert are

designed.

The electro-technological part of the laboratory is made up of a system of cable routes, measurement and control cables, a control and visualization system. The hydraulic circuit is operated via a 10” touch display which

is a part of the electric switchboard.